The production landscape is constantly evolving, and automation is in the forefront of the transformation. especially, automatic liquid filling is revolutionizing industries by maximizing efficiency, precision, and Over-all efficiency. Choosing the proper liquid filling equipment on the market is critical for enterprises seeking to keep aggressive and meet up with the expanding calls for of the industry. This information will explore the latest innovations in liquid filling machines, spotlight the importance of picking the right maker, and provide steering on choosing the great product for your personal distinct sector application.

Table of contents:

improvements in Liquid Filling equipment: What top brands offer you in 2025

Why selecting the suitable Liquid Filling equipment maker Impacts Your Output Quality

Liquid Filling Machine available: Which product suits Your sector Application ideal?

improvements in Liquid Filling devices: What major brands give in 2025

main liquid filling equipment manufacturer are consistently pushing the boundaries of know-how, introducing progressive attributes that increase overall performance and effectiveness. One important development is The combination of advanced sensor technology, enabling true-time checking of fill degrees and automated changes to keep up precision. Yet another significant innovation is the development of much more flexible equipment that could take care of a broader number of liquid viscosities and container sizes, minimizing the necessity for a number of devices. Improved cleaning and sterilization units will also be getting prominence, particularly in industries with strict hygiene specifications. Furthermore, suppliers are incorporating clever engineering, permitting for remote checking, diagnostics, and predictive maintenance, reducing downtime and maximizing productivity. using robotics and automation is additionally rising, enabling fully automatic filling traces with negligible human intervention. When assessing distinct devices, think about these improvements and select a design that incorporates the newest engineering to enhance your creation procedures.

Why Choosing the ideal Liquid Filling device company Impacts Your Output Quality

Selecting the proper liquid filling device maker contains a profound influence on your output excellent. A highly regarded company not simply delivers significant-good quality devices but also offers experience, aid, in addition to a motivation to the accomplishment. A major-tier producer will work closely along with you to know your unique desires and propose quite possibly the most acceptable alternatives. they are going to give custom made machine configurations to enhance your generation procedures and make certain constant, accurate filling. In addition, a trusted maker will supply extensive coaching and technical assistance to guarantee your machines work easily and effectively. within the function of a problem, they can supply prompt and dependable mend solutions to reduce downtime. By partnering with a trusted manufacturer, you gain access to a wealth of knowledge and practical experience that can help you help your product excellent, reduce squander, and enhance your In general operational efficiency. It’s crucial that you contemplate such things as certifications and market status when generating your choice.

Liquid Filling equipment available for purchase: Which product Fits Your field software very best?

acquiring the proper liquid filling equipment for sale requires mindful consideration of the precise industry software. distinct industries have unique wants, and The best device will range according to the kind of liquid staying loaded, the container measurement, and the desired manufacturing amount.

prescribed drugs: Require equipment with large precision, sterilization abilities, and compliance with demanding regulatory expectations. Aseptic filling equipment are sometimes crucial.

Cosmetics: demand from customers machines that preserve aesthetic enchantment and prevent spills. Precise quantity Management and gentle handling are crucial.

meals and Beverage: have to have devices which are straightforward to clean and sanitize, usually necessitating chrome steel construction to satisfy hygiene specifications.

chemical substances: Necessitate equipment created from corrosion-resistant elements and Geared up with safety characteristics to safeguard employees.

private Care: Benefit from adaptable machines that may take care of many different liquid viscosities and container styles.

prior to making a order, very carefully assess your unique requirements and go with a design which is personalized on your business software. think about aspects which include filling accuracy, speed, versatility, and ease of routine maintenance.

The future of automated filling is brilliant, with innovations frequently improving effectiveness and precision. By carefully assessing your requirements, picking out the suitable liquid filling machine for sale, and partnering with a dependable liquid filling device here producer, it is possible to optimize your output procedures, boost your output good quality, and accomplish sustained accomplishment while in the competitive marketplace. Embrace automation and spend money on the future of your enterprise now.

Tia Carrere Then & Now!

Tia Carrere Then & Now! Daniel Stern Then & Now!

Daniel Stern Then & Now! Brandy Then & Now!

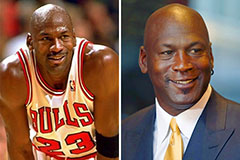

Brandy Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!